MT818/EN 50525 Certified Flexible Power Cable 1.9/3.3kV Copper Conductor EPDM Insulation CR Sheath for Coal Mine Mining Cable

-

Email: info@xijiangyuecable.com

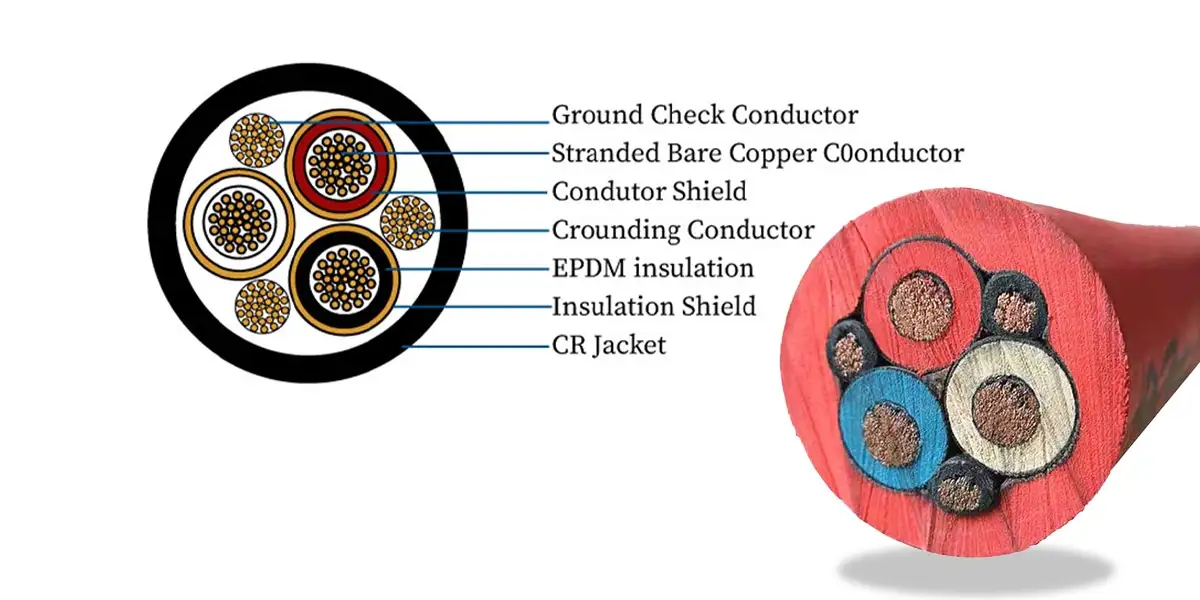

Structure

Description

Application

High-voltage cables are essential for power grids, renewable energy integration, industrial plants, and long-distance subsea transmission projects.

Main Characteristics

Product Overview

Our Mining Cable is specially designed for demanding applications in coal mines, tunneling, and underground mining operations.

Certified to MT818, IEC 60502, and MSHA standards, it ensures superior safety, flexibility, and durability in extreme conditions.

Key Features

✔ Robust Construction – Features EPDM insulation + CR (Chloroprene Rubber) sheath for excellent abrasion, oil, and chemical resistance.

✔ High Voltage Options – Available in 0.6/1kV, 1.9/3.3kV, and 3.6/6kV ratings for various mining equipment.

✔ Flexible & Durable – Reinforced with steel wire armor (SWA) or tinned copper braid for enhanced tensile strength and bending performance.

✔ Flame Retardant & Explosion Proof – Complies with ATEX/IECEx for use in hazardous (Zone 1/Zone 2) environments.

✔ International Certifications – Meets EN 50525 (EU), UL 44/CSA (North America), and AS/NZS 2802 (Australia/New Zealand).

| Parameter | Details |

| Conductor | Bare/Tinned Copper (Class 5/6 Flexible Stranded) |

| Insulation | EPDM/XLPE (Excellent Thermal stability) |

| Sheath Material | CR/CPE (Oil & Flame Retardant) |

| Voltage Rating | 0.6/1kv, 1.9/3.3kV, 3.6/6kV |

| Temperature Range | -40°C to +90°C (Short-term up to 130°C) |

| Standards | MT818, IEC 60502, MSHA, EN 50525, UL 44 |

| Voltage level:0.6/1kV | ||||||||||||||||||

| Number of cores | Conductor Diameter | Conductor cross section | Insulation Thickness | Resistance | No armor | With Steel Armor | Steel Wire Armor | |||||||||||

| (mm) | (mm2) | (mm) | (Ω/km) | Sheath Thickness | Cable outer diameter | weight | Current | Sheath Thickness | Strip Thickness | Cable Outer Diameter | weight | Current | Sheath Thickness | Wire Diameter | Cable Outer Diameter | weit | Cnt | |

| (mm) | (mm) | (kg/km) | (A) | (mm) | (mm) | (mm) | (kg/km) | (A) | (mm) | (mm) | (mm) | km) | (A) | |||||

| Three cores | 1.4 | 1.5 | 0.7 | 12.1 | 1.8 | 10.4 | 121 | 27/20 | ||||||||||

| 1.8 | 2.5 | 0.7 | 7.41 | 1.8 | 11.3 | 159 | 35/26 | 1.8 | 0.2×2 | 13.1 | 255 | 35/26 | ||||||

| 2.3 | 4 | 0.7 | 4.61 | 1.8 | 12.2 | 210 | 45/34 | 1.8 | 0.2×2 | 14 | 317 | 45/34 | ||||||

| 2.8 | 6 | 0.7 | 3.08 | 1.8 | 13.4 | 280 | 57/43 | 1.8 | 0.2×2 | 15.2 | 397 | 57/43 | ||||||

| 3.8 | 10 | 0.7 | 1.83 | 1.8 | 16.1 | 431 | 77/60 | 1.8 | 0.2×2 | 17.9 | 561 | 77/60 | 1.8 | 0.8 | 21.7 | 1049 | 65/80 | |

| 4.8 | 16 | 0.7 | 1.15 | 1.8 | 18.4 | 634 | 105/83 | 1.8 | 0.2×2 | 20.2 | 773 | 105/83 | 1.8 | 0.8 | 24 | 1323 | 85/100 | |

| 6 | 25 | 0.9 | 0.727 | 1.8 | 22.1 | 947 | 125/105 | 1.8 | 0.2×2 | 23.9 | 1130 | 125/105 | 1.8 | 1.6 | 27.7 | 1779 | 115/130 | |

| 7 | 35 | 0.9 | 0.524 | 1.8 | 24.6 | 1254 | 155/125 | 1.8 | 0.2×2 | 26.4 | 1458 | 155/125 | 1.8 | 1.6 | 30.2 | 2174 | 145/155 | |

| 8.3 | 50 | 1 | 0.387 | 1.8 | 27.9 | 1660 | 185/160 | 1.8 | 0.5×2 | 29.7 | 1893 | 185/160 | 1.9 | 1.6 | 33.9 | 2729 | 175/185 | |

| 9.8 | 70 | 1.1 | 0.268 | 1.9 | 32.8 | 2353 | 225/200 | 2 | 0.5×2 | 36.2 | 2967 | 225/200 | 2 | 2 | 39.6 | 3854 | 220/225 | |

| 11.5 | 95 | 1.1 | 0.193 | 2 | 37.1 | 3179 | 270/245 | 2 | 0.5×2 | 40.5 | 3872 | 270/245 | 2.2 | 2 | 43.9 | 4862 | 270/270 | |

| 12.9 | 120 | 1.2 | 0.153 | 2.1 | 41.2 | 3983 | 310/285 | 2.1 | 0.5×2 | 44.6 | 4753 | 310/285 | 2.3 | 2 | 48 | 5840 | 315/305 | |

| 14.5 | 150 | 1.4 | 0.124 | 2.3 | 45.8 | 4909 | 345/325 | 2.3 | 0.5×2 | 49.2 | 5762 | 345/325 | 2.4 | 2.5 | 53.8 | 7498 | 360/345 | |

| 16 | 185 | 1.6 | 0.0991 | 2.4 | 50.9 | 6104 | 390/375 | 2.4 | 0.5×2 | 54.3 | 7051 | 390/375 | 2.6 | 2.5 | 59.3 | 9020 | 420/390 | |

| 18.3 | 240 | 1.7 | 0.0754 | 2.6 | 57.4 | 7941 | 450/440 | 2.6 | 0.5×2 | 60.8 | 9006 | 450/440 | 2.7 | 2.5 | 66 | 11237 | 500/455 | |

| 20.5 | 300 | 1.8 | 0.0601 | 2.8 | 63.4 | 9890 | 515/505 | 2.7 | 0.5×2 | 66.8 | 11067 | 515/505 | 2.9 | 2.5 | 72 | 13521 | 550/520 | |