Factory Bulk Supply XLPE Insulated PVC Sheathed 06/1kV Low Voltage Power Cable for Industrial Marine Overhead Computer

-

Email: info@xijiangyuecable.com

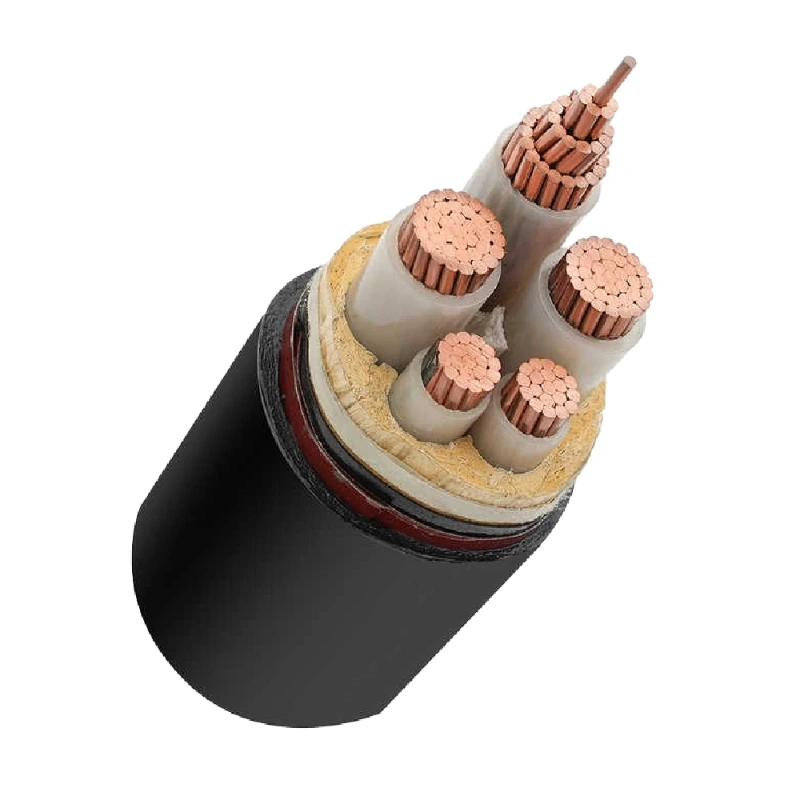

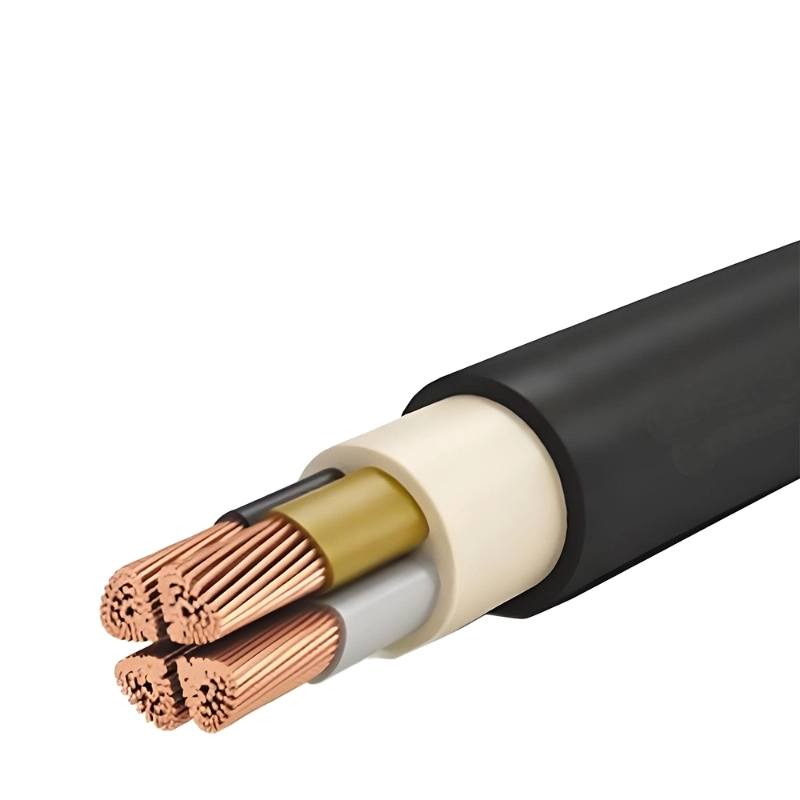

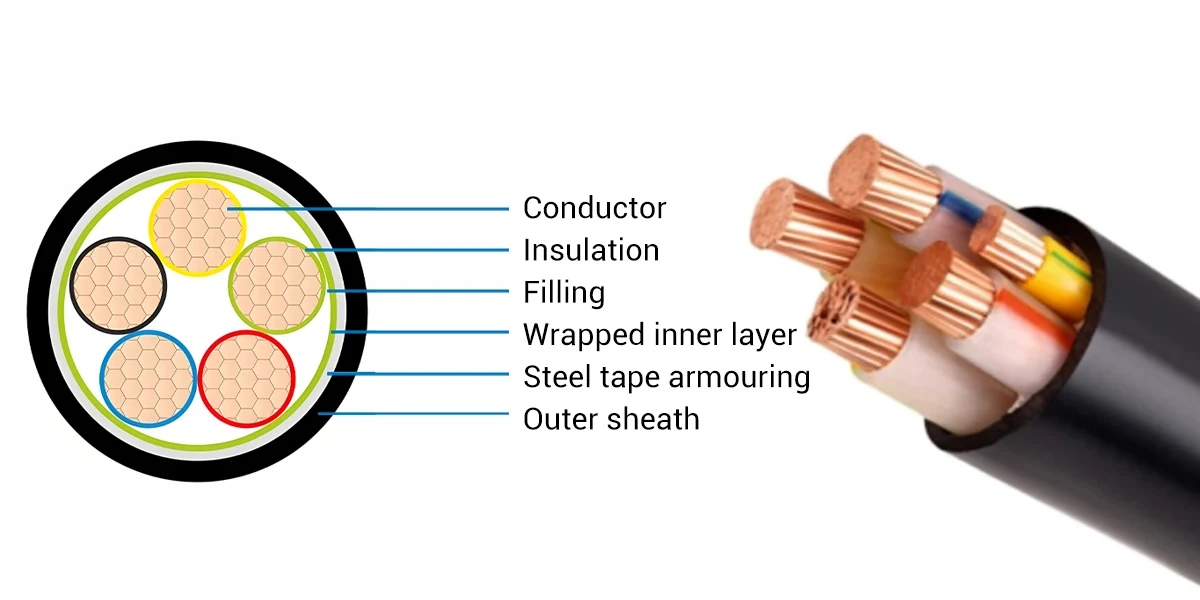

Structure

Description

Application

Cross-linked polyethylene insulated power cables is characterized with high mechanical strength,strong resistance to environmental stress,excellent electrical properties ,powerful resistance to chemical attack.In addition,the light and simple products are user-friendly.This product is suitable and designed for power transmission and distribution system of rated voltage 0.6/1kv.In terms of the main feature of anti-flaming cable,the cable is not liable to continued ignition is only limited to a certain scope applicable to power station ,subway ,tunnel ,high-rise building,large industrial and mining enterprise,oil field,coal mine and other places of intensive distributed electric cables.

Main Characteristics

What is the difference between YJV and YJV-22 cables?

yjv cable vs yjv-22

Structure and application:

YJV cables are made of cross-linked polyethylene (XLPE) insulation and PVC sheaths. yjv is suitable for indoor use with very low risk of mechanical damage. yjv-22 cables have a metal armor in addition to the same insulation and sheath. This makes it ideal for underground or external installations that are susceptible to mechanical stress.

Resistance and protection:

YJV cables have excellent electrical insulation, mechanical protection and environmental resistance. It is well suited for environments with low physical requirements. YJV-22 cable is armored with steel tape. It has excellent resistance to impact and extrusion and is suitable for industrial environments and areas with physical disturbances.

Selection Criteria:

The choice between YJV and YJV-22 cables depends on environmental conditions and mechanical stress; YJV cables are best suited for protected indoor environments, while YJV-22 cables are suitable for outdoor or underground environments where the risk of physical damage is high.

YJV Cable Conclusion

An explanation of the field of YJV cables reveals their importance in a variety of environments, from residential to industrial applications. We dissect the structure, applications, and key differences between yjv cables and yjv22. We believe we have come to this point with a clearer understanding of cable selection. In the meantime, if you want to go further to get a comprehensive cable solution or obtain yjv series cables price, xijiangyue Cable manufacturer offers you a way to get quality products

Multiple models and specifications

XLPE INSULATED LV ARMORED POWER CABLES

1. Scope

(1) Operating temperature: Maximum continuous conductor temperature: 90°C

(2) Short-circuit temperature: 250°C (max. duration 5 seconds)

(3) Bending radius:

- Single-core cable: 12×D

- Multi-core cable: 10×D

D = Cable overall diameter (mm)

(4) Installation temperature: Minimum laying temperature: -5°C

(5) Current rating parameters:

- Ambient temperature (air): 40°C

- Ambient temperature (burial): 25°C

- Soil thermal resistivity: 1.5 K·m/W

2. Construction

(1) Conductor: Stranded copper (Class 2)

(2) Insulation: XLPE

(3) Sheath: LSZH termite resistant

(4) Standards: IEC 60502-1, IEC 60332-1-2

(5) Voltage rating: 0.6/1 kV

Specification

Table 1 Single core CU/PVC/PVC IEC 60502-1

| No. of cores | Approx. diameter of conductor | Nominal thickness of insulation | Nominal thickness of outer sheath | Approx. OD of cable | Approx. weight of cable | ||

| & CSA | |||||||

| Phase | Earth | Phase | Earth | ||||

| mm | mm | mm | mm | mm | mm | kg/km | |

| 1C1.5 | 1.56 | / | 0.8 | / | 1.4 | 6 | 52.1 |

| 1C2.5 | 2.04 | / | 0.8 | / | 1.4 | 6.5 | 65.9 |

| 1C4 | 2.55 | / | 1 | / | 1.4 | 7.5 | 91.4 |

| 1C6 | 3.1 | / | 1 | / | 1.4 | 8 | 115.3 |

| 1C10 | 4 | / | 1 | / | 1.4 | 8.9 | 159.1 |

| 1C16 | 5 | / | 1 | / | 1.4 | 9.9 | 222.3 |

| 1C25 | 6.1 | / | 1.2 | / | 1.4 | 11.4 | 325.7 |

| 1C35 | 7.2 | / | 1.2 | / | 1.4 | 12.5 | 423.5 |

| 1C50 | 8.4 | / | 1.4 | / | 1.4 | 14.1 | 557.5 |

| 1C70 | 10 | / | 1.4 | / | 1.4 | 15.7 | 763 |

| 1C95 | 12 | / | 1.6 | / | 1.5 | 18.4 | 1046.5 |

| 1C120 | 13 | / | 1.6 | / | 1.5 | 19.4 | 1277.4 |

| 1C150 | 14.9 | / | 1.8 | / | 1.6 | 21.9 | 1581.5 |

| 1C185 | 16.5 | / | 2 | / | 1.7 | 24.1 | 1956.5 |

| 1C240 | 18.4 | / | 2.2 | / | 1.8 | 26.6 | 2537.3 |

| 1C300 | 21 | / | 2.4 | / | 1.9 | 29.8 | 3164.4 |

| 1C400 | 23.4 | / | 2.6 | / | 2 | 32.9 | 4022.4 |

| 1C500 | 26.6 | / | 2.8 | / | 2.1 | 36.7 | 5111.8 |

| 1C630 | 30 | / | 2.8 | / | 2.2 | 40.3 | 6445.8 |

| 1C800 | 34 | / | 2.8 | / | 2.3 | 44.5 | 8137.1 |

Table 2 Two core CU/PVC/PVC IEC 60502-1

| No. of cores | Approx. diameter of conductor | Nominal thickness of insulation | Nominal thickness of outer sheath | Approx. OD of cable | Approx. weight of cable | ||

| & CSA | |||||||

| Phase | Earth | Phase | Earth | ||||

| mm | mm | mm | mm | mm | mm | kg/km | |

| 2C1.5 | 1.56 | / | 0.8 | / | 1.8 | 10.7 | 128.5 |

| 2C2.5 | 2.04 | / | 0.8 | / | 1.8 | 11.6 | 161 |

| 2C4 | 2.55 | / | 1 | / | 1.8 | 13.5 | 222.4 |

| 2C6 | 3.1 | / | 1 | / | 1.8 | 14.6 | 277.2 |

| 2C10 | 4 | / | 1 | / | 1.8 | 16.4 | 377.5 |

| 2C16 | 5 | / | 1 | / | 1.8 | 18.4 | 519.5 |

| 2C25 | 6.1 | / | 1.2 | / | 1.8 | 21.4 | 753.6 |

| 2C35 | 7.2 | / | 1.2 | / | 1.8 | 23.6 | 971.5 |

| 2C50 | 8.4 | / | 1.4 | / | 1.8 | 26.9 | 1275.8 |

| 2C70 | 10 | / | 1.4 | / | 1.9 | 30.9 | 1754.1 |

| 2C95 | 12 | / | 1.6 | / | 2 | 35.9 | 2393.8 |

| 2C120 | 13 | / | 1.6 | / | 2.1 | 38.1 | 2907.7 |

| 2C150 | 14.9 | / | 1.8 | / | 2.2 | 43 | 3600.9 |

| 2C185 | 16.5 | / | 2 | / | 2.4 | 47.4 | 4455 |

| 2C240 | 18.4 | / | 2.2 | / | 2.6 | 52.4 | 5747.9 |

| 2C300 | 21 | / | 2.4 | / | 2.7 | 58.7 | 7156 |

Table 3 Three core CU/PVC/PVC IEC 60502-1

| No. of cores | Approx. diameter of conductor | Nominal thickness of insulation | Nominal thickness of outer sheath | Approx. OD of cable | Approx. weight of cable | ||

| & CSA | |||||||

| Phase | Earth | Phase | Earth | ||||

| mm | mm | mm | mm | mm | mm | kg/km | |

| 3C1.5 | 1.56 | / | 0.8 | / | 1.8 | 11.2 | 154.2 |

| 3C2.5 | 2.04 | / | 0.8 | / | 1.8 | 12.2 | 197.7 |

| 3C4 | 2.55 | / | 1 | / | 1.8 | 14.2 | 279 |

| 3C6 | 3.1 | / | 1 | / | 1.8 | 15.4 | 354.4 |

| 3C10 | 4 | / | 1 | / | 1.8 | 17.4 | 492.9 |

| 3C16 | 5 | / | 1 | / | 1.8 | 19.5 | 691.8 |

| 3C25 | 6.1 | / | 1.2 | / | 1.8 | 22.8 | 1019.1 |

| 3C35 | 7.2 | / | 1.2 | / | 1.8 | 25.2 | 1327.3 |

| 3C50 | 8.4 | / | 1.4 | / | 1.8 | 28.7 | 1753.8 |

| 3C70 | 10 | / | 1.4 | / | 2 | 33.2 | 2442.5 |

| 3C95 | 12 | / | 1.6 | / | 2.1 | 38.6 | 3341.9 |

| 3C120 | 13 | / | 1.6 | / | 2.2 | 40.9 | 4081.1 |

| 3C150 | 14.9 | / | 1.8 | / | 2.3 | 46.1 | 5051.4 |

| 3C185 | 16.5 | / | 2 | / | 2.5 | 50.9 | 6255.4 |

| 3C240 | 18.4 | / | 2.2 | / | 2.7 | 56.3 | 8099.7 |

| 3C300 | 21 | / | 2.4 | / | 2.9 | 63.2 | 10121 |

Table 4 Four core CU/PVC/PVC IEC 60502-1

| No. of cores | Approx. diameter of conductor | Nominal thickness of insulation | Nominal thickness of outer sheath | Approx. OD of cable | Approx. weight of cable | ||

| & CSA | |||||||

| Phase | Earth | Phase | Earth | ||||

| mm | mm | mm | mm | mm | mm | kg/km | |

| 4C1.5 | 1.56 | / | 0.8 | / | 1.8 | 12 | 184.8 |

| 4C2.5 | 2.04 | / | 0.8 | / | 1.8 | 13.2 | 240.4 |

| 4C4 | 2.55 | / | 1 | / | 1.8 | 15.5 | 344.1 |

| 4C6 | 3.1 | / | 1 | / | 1.8 | 16.8 | 441.7 |

| 4C10 | 4 | / | 1 | / | 1.8 | 19 | 621.3 |

| 4C16 | 5 | / | 1 | / | 1.8 | 21.4 | 880.7 |

| 4C25 | 6.1 | / | 1.2 | / | 1.8 | 25.1 | 1307.7 |

| 4C35 | 7.2 | / | 1.2 | / | 1.8 | 27.7 | 1711.4 |

| 4C50 | 8.4 | / | 1.4 | / | 1.9 | 31.8 | 2283.2 |

| 4C70 | 10 | / | 1.4 | / | 2.1 | 36.7 | 3181.4 |

| 4C95 | 12 | / | 1.6 | / | 2.2 | 42.8 | 4358.5 |

| 4C120 | 13 | / | 1.6 | / | 2.4 | 45.6 | 5352.4 |

| 4C150 | 14.9 | / | 1.8 | / | 2.5 | 51.4 | 6623.4 |

| 4C185 | 16.5 | / | 2 | / | 2.7 | 56.7 | 8201.1 |

| 4C240 | 18.4 | / | 2.2 | / | 2.9 | 62.7 | 10626.5 |

| 4C300 | 21 | / | 2.4 | / | 3.1 | 70.4 | 13276 |

Table 5 Five core CU/PVC/PVC IEC 60502-1

| No. of cores | Approx. diameter of conductor | Nominal thickness of insulation | Nominal thickness of outer sheath | Approx. OD of cable | Approx. weight of cable | ||

| & CSA | |||||||

| Phase | Earth | Phase | Earth | ||||

| mm | mm | mm | mm | mm | mm | kg/km | |

| 5C1.5 | 1.56 | / | 0.8 | / | 1.8 | 12.9 | 217.1 |

| 5C2.5 | 2.04 | / | 0.8 | / | 1.8 | 14.2 | 285.2 |

| 5C4 | 2.55 | / | 1 | / | 1.8 | 16.8 | 412.1 |

| 5C6 | 3.1 | / | 1 | / | 1.8 | 18.2 | 532.5 |

| 5C10 | 4 | / | 1 | / | 1.8 | 20.7 | 754.5 |

| 5C16 | 5 | / | 1 | / | 1.8 | 23.4 | 1075.7 |

| 5C25 | 6.1 | / | 1.2 | / | 1.8 | 27.5 | 1605.1 |

| 5C35 | 7.2 | / | 1.2 | / | 1.9 | 30.6 | 2120.2 |

| 5C50 | 8.4 | / | 1.4 | / | 2.1 | 35.4 | 2846.2 |

| 5C70 | 10 | / | 1.4 | / | 2.2 | 40.5 | 3942.6 |

| 5C95 | 12 | / | 1.6 | / | 2.4 | 47.5 | 5426.9 |

| 5C120 | 13 | / | 1.6 | / | 2.5 | 50.4 | 6639.2 |

| 5C150 | 14.9 | / | 1.8 | / | 2.7 | 57 | 8243.7 |

| 5C185 | 16.5 | / | 2 | / | 2.9 | 62.9 | 10204.8 |

| 5C240 | 18.4 | / | 2.2 | / | 3.1 | 69.6 | 13223.2 |

| 5C300 | 21 | / | 2.4 | / | 3.3 | 78.1 | 16518.2 |