Special Flexible Duty Power Wire 06/1kV Wind Energy Generation Systems Copper Conductor EPR Rubber Sheathed Wind Power Cable

-

Email: info@xijiangyuecable.com

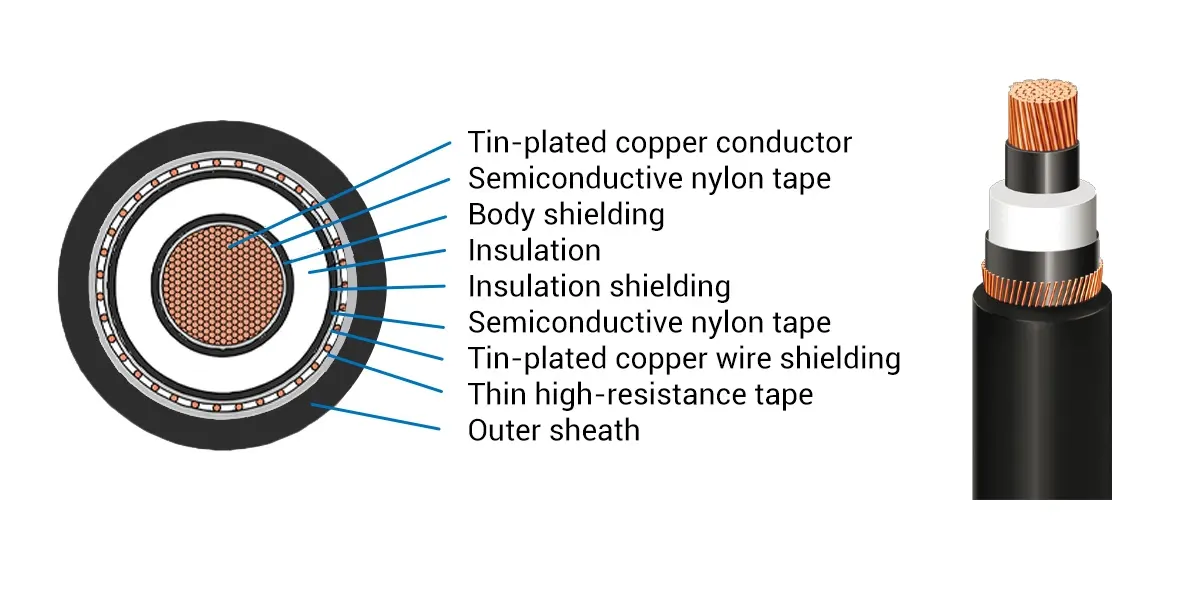

Structure

Description

Application

For fixed installation in most areas and on open deck on shipboard and offshore units.

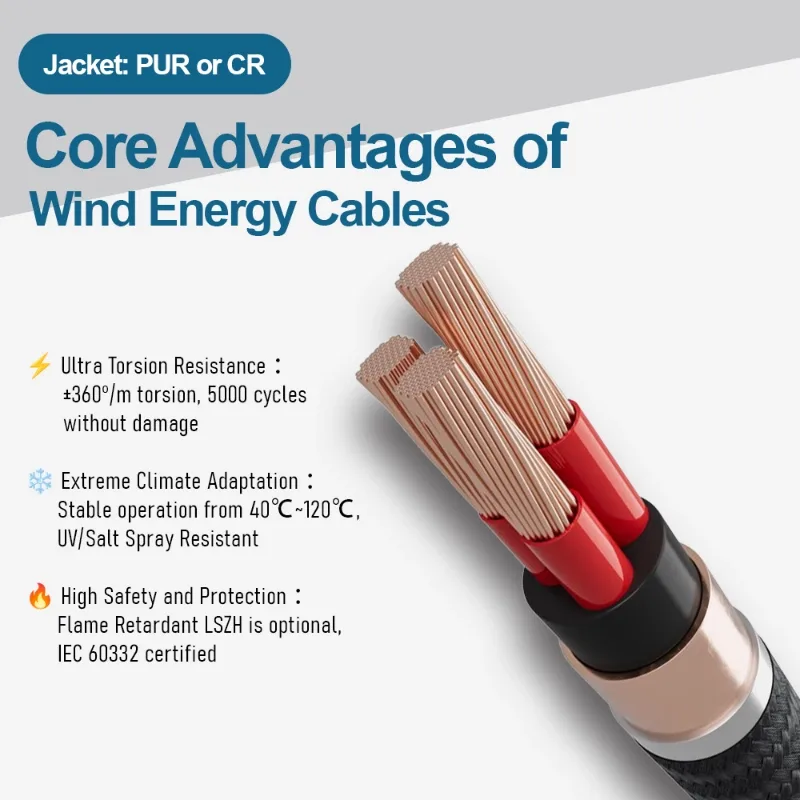

Main Characteristics

Types of Wind Turbine Cables

The voltage level in the turbines is a low 600 V, which enables the use of any number of industry-standard technologies. Several cables (possibly eight to ten) supply this low voltage to the step-up transformer at the base of the power station.

1KV/3KV Tinned Copper Shielded LSZH Turbo Cable

- Conductor: Bare copper stranded wire

- Insulation: EPR (Ethylene Propylene Rubber)

- Shield: TWCB (Tinned Copper Wire Braid)

- Sheath: HF-EVA (Halogen Free Ethylene Vinyl Acetate)/HF XL-EVA(Halogen-free cross-linked ethylene vinyl acetate)

- Sheath Color: Black

- Rated voltage Uo/U: 0.6/1kV/1.8/3kV

- Temperature Rating: fixed -40℃ +90℃, bending -35℃ +90℃

- Minimum Bend Radius: Fixed 4x OD, Bend 6x OD

- Torsional resistance: ±100°/meter

- Maximum tensile load: 15N/mm2 (at work)

- Product Specifications: 4X1.5mm², 4X4mm², 5X2.5mm², 12X1.5mm2, 12X2.5mm2, 25X0.75mm2, 25X1mm2, 32X1.5mm², 42X1.5mm2/25mm²、35mm²、50mm²、70mm²、95mm²、120mm²、150mm²、185mm²、240mm²、300mm²、400mm²。

Implementing Standards: IEC 60502-1, IEC 60228, EN 50363, HD 22.13, flame retardant by IEC 60332-1, low smoke zero halogen by IEC 60754, IEC 61034.

Areas of Application: Anti-twist ring shielded power cables are designed for, special application conditions in wind turbines, medium mechanical stress, suitable for operation outdoors or under the following conditions, permanent effects of seawater, oil, UV, and ozone resistant.

The following is a detailed description of wind power cables:

1. Product Overview

Design Purpose: Used for power, signal and control transmission in tower, nacelle, rotor blades and other parts of wind power generation system.

Use: Connecting generator, transformer, control system and other equipment.

Application areas:

Wind turbines.

Offshore wind farms.

Onshore wind farms.

2. Structural design

The structure of wind power cables is specially designed to meet the extreme environmental requirements of wind power systems:

Conductor:

Material: High purity copper conductor (usually tinned copper).

Construction: Multi-stranded fine copper wires (usually Class 5 or Class 6) to ensure high flexibility.

Insulation:

Material: commonly cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR).

Function: To isolate the conductors and provide excellent electrical insulation.

Shield (optional)

Structure: Copper wire braid shielding or copper tape shielding.

Function: Effective shielding against electromagnetic interference (EMI).

Filler layer: Material: Aramid fiber or similar material.

Function: Enhance the tensile strength and flexibility of the cable.

Sheath layer: Material: commonly used PUR (polyurethane), TPE (thermoplastic elastomer) or CPE (chlorinated polyethylene).

Characteristics: low temperature resistance, oil resistance, chemical resistance, adapted to wind power generation environment.

3. Performance characteristics

Low temperature resistance:

The working temperature range is from -40°C to 105°C, which is suitable for use in cold areas.

Torsion resistance: Suitable for wind turbine torsion movement, preventing cable fatigue breakage.

Tensile strength: The filler layer is designed to enhance the tensile properties and adapt to high mechanical stresses.

Chemical resistance: Resistant to oil, acid and alkali, suitable for offshore wind farms and other corrosive environments.

Weather Resistance:

UV and oxidation resistant, suitable for long-term outdoor use.

Shielding performance (optional):

Anti-electromagnetic interference, suitable for high interference environment.

Flame retardant:

Conforms to flame retardant standards (e.g. UL VW1 or IEC 60332).

Translated with DeepL.com (free version)

| parameters | typical value |

| Conductor specifications | 0.5 mm²to 300 mm² |

| Insulation Material | XLPE, EPR, etc. |

| Shield Structure | Copper wire braid or copper tape shield (optional) |

| Sheath Material | PUR, TPE, CPE, etc. |

| Operating Temperature Range | -40°C to 105°C |

| Rated Voltage | 600v, 1kv, 3.6kV or higher |

| Flame retardant grade | UL VW1, IEC 60332, etc. |

|

Normal area |

Conductor Construction | Outside Diamete | Sheath Thickne |

|

(mm²) |

(mm²) | (mm²) | (mm²) |

| 1.5 | 7/0.52 | 6 | 1.5 |

| 2.5 | 7/0.67 | 6 | 1.5 |

| 4 | 7/0.84 | 7 | 1.5 |

| 6 | 7/1.04 | 7 | 1.5 |

| 10 | 7/1.35 | 8 | 1.5 |

| 16 | 7/1.7 | 9 | 1.5 |

| 25 | 7/2.14 | 10 | 1.5 |

| 35 | 7/2.52 | 12 | 1.5 |

| 50 | 19/1.78 | 13 | 1.5 |

| 70 | 19/2.14 | 14 | 1.5 |

| 95 | 19/2.52 | 16 | 1.5 |

| 120 | 37/2.03 | 18 | 1.5 |

| 150 | 37/2.25 | 21 | 2 |

| 185 | 37/2.52 | 23 | 2 |

| 240 | 61/2.25 | 25 | 2 |

| 3x1.5 | 3x7/0.52 | 10 | 1.5 |

| 3x2.5 | 3x7/0.67 | 11 | 1.5 |

| 3x4.0 | 3x7/0.84 | 12 | 1.5 |

| 3x6.0 | 3x7/1.04 | 13 | 1.5 |

| 3x10.0 | 3x7/1.35 | 15 | 1.5 |

| 3x16 | 3x7/1.7 | 17 | 2 |

| 3x25 | 3x7/2.14 | 21 | 2 |

| 3x35 | 3x7/2.52 | 23 | 2 |

| 3x50 | 3x19/1.78 | 27 | 2 |

| 3x70 | 3x19/2.14 | 30 | 2.5 |

| 3x95 | 3x19/2.52 | 34 | 2.5 |

| 3×120 | 3×37/2.03 | 38 | 2.5 |

| 3×150 | 3×37/2.25 | 42 | 2.5 |

| 3×185 | 3×37/2.52 | 45 | 2.5 |

| 3×240 | 3×61/2.25 | 51 | 3 |